Project information

Our client had to set up cabins allowing him to carry out leak tests on his products in series or in development, allowing him to ensure compliance with the standards in force and the standardized test procedures.

Montanier provided a positive response, and designed two cabins allowing Schneider Electric to carry out its tests in accordance with the standard and in a repeatable manner for:

- 1 cabin for IP54, IP55 and NEMA4 testing

- 1 cabin for IP69k testing

During this design, Montanier studied the standards in force, and technically transcribed their strict application in the cabins.

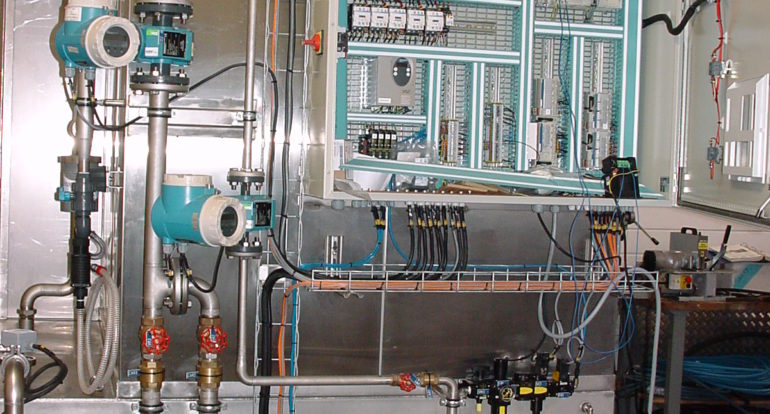

The cabin for IP54, IP55 and NEMA4 test consists of:

– Raw water treatment

– A stainless steel cabin for high-flow water spraying

– A rotary table with EST mounting trolley

– A buffer tank

– A high flow pump

– An electrical power cabinet

– An HMI box with touch screen

– a spray nozzle outside the cabin

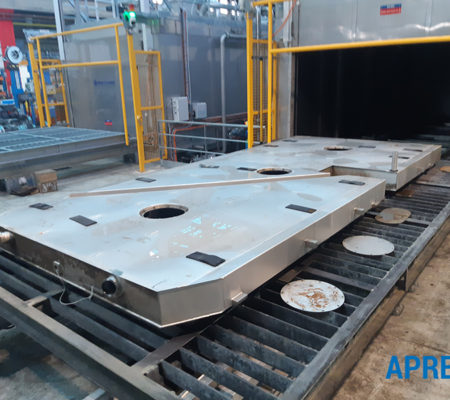

The cabin for the IP69K test consists of:

– Raw water treatment

– A stainless steel cabin for spraying hot water under pressure

– A rotary table with EST mounting trolley

– A hot water buffer tank 80°C

– At 60°C hot water buffer tank for detergent

– A high pressure pump with pressure, flow and temperature control sensor

– An electrical power cabinet

– An HMI box with touch screen

– A detergent and disinfectant dosage

The cycle takes place in automatic mode according to: “Test according to DIN 40 050 – Part 9”

Complete cycle, including successive “switching” of the water to the 4 nozzles at 0°, 30°, 60° and 90°.

Fixed temperature, pressure and duration of spraying (modifiable only by password).

Turntable operated in one direction at fixed speed (modifiable only by password).

Extraction of vapors to the outside of the enclosure.

Operation with recycled water (recycling tank no. 1).

Security: Locked glass door.

+(33) 2 41 67 11 11

+(33) 2 41 67 11 11