Project information

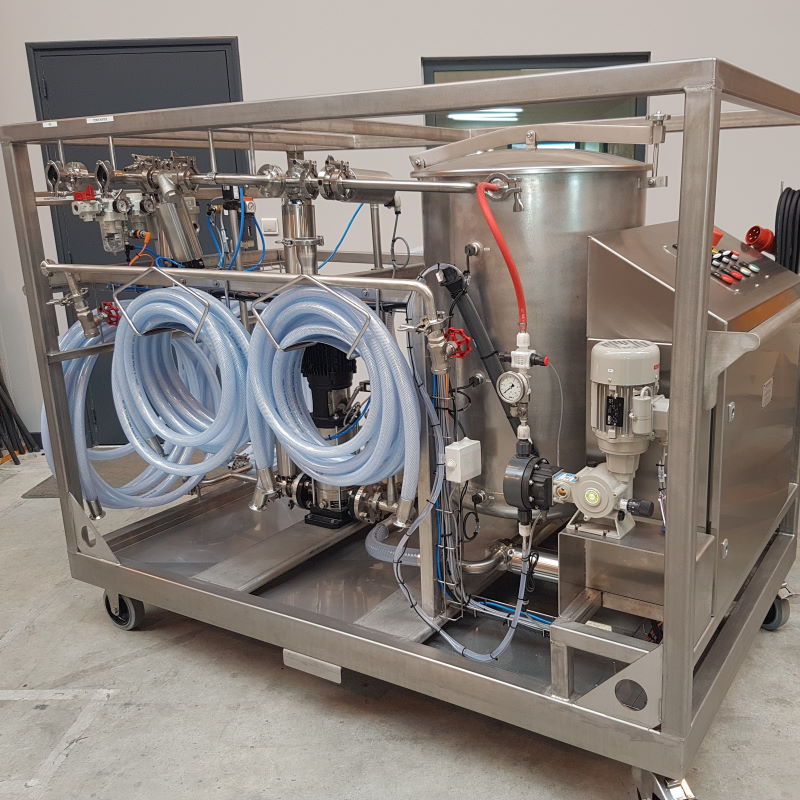

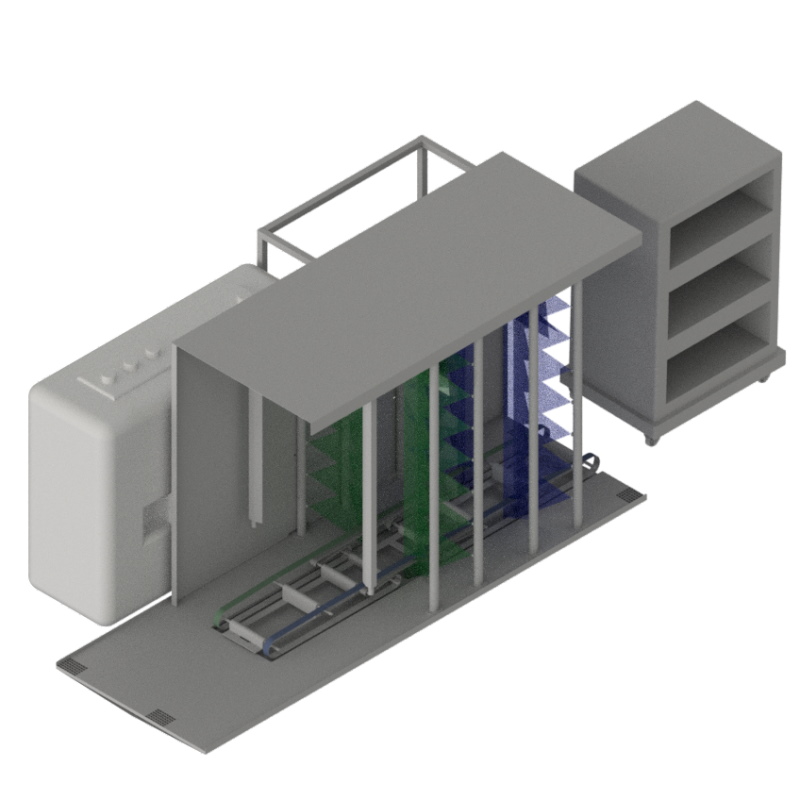

Our R&D team developed a multi-format container washing system. Our client needed a machine capable of washing the inside and outside of multi-format containers used in the manufacture of non-injectable virus testing kits.

Furthermore, he wanted traceability of washing cycles in compliance with FDA 21 CFR PART 11.

In light of the client's specific expectations, we created a custom-made machine that meets the following criteria:

- Interior design without roughness or retention.

- Interior with mirror-polished finish in 316L grade stainless steel.

- Design and manufacture of FDA-certified polymer shaped parts for securing various containers.

- Orbital welding whenever possible with traceability of each weld.

- Integration of a high-pressure washing head 110 bar 80 l/min for the internal washing of containers.

- Addition of wash ramps to the upper and lower parts of the cabin to impact all external surfaces of the containers to be washed.

- Integration of a conductivity probe for validation of rinsing water.

- Cabin sealing by inflatable seal.

- Saving and printing tickets at the end of the cycle.

+(33) 2 41 67 11 11

+(33) 2 41 67 11 11