Project information

MONTANER has developed numerous specific washing areas for its clients. Local authorities have been calling on MONTANER for years for the design and construction of their vehicle washing areas.

Based on feedback from MONTANIER's experience with the various community sites, we apply the improvements to our new equipment.

The wash bays for BOM and other vehicles consist of various underground and above-ground equipment, in a technical room and on the wash bays.

A typical vehicle wash bay for local authorities is equipped with:

- 1 elevated access walkway, allowing the washing of the roofs of the BOMs.

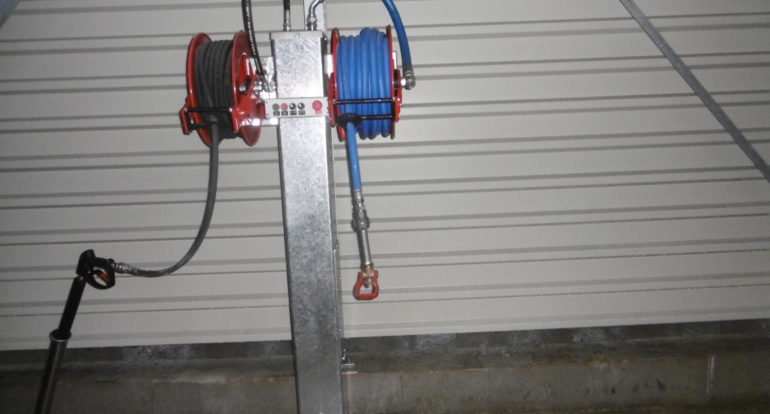

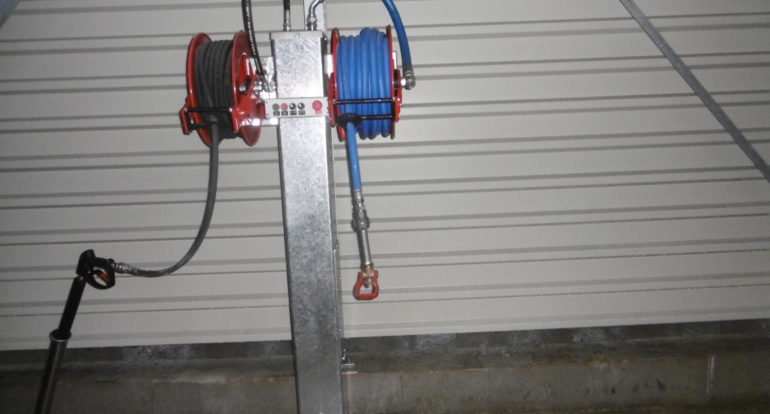

- 1 or 2 washing stations on automatic reel, fixed on a post, allowing ergonomic work at height.

- 1 Low Pressure – High Flow (cold water) washing station, on the floor with automatic hose reels.

- One central drainage channel with a perpendicular channel at the end of the track, equipped with waste collection bins. The weight and handling of these bins are designed to ensure optimal ergonomics for the operator.

- 1 EF (cold water) underbody wash station with 3 fixed ramps equipped with flat jet nozzles. This system consists of one horizontal ramp for underbody washing and 2 vertical ramps for washing the sills, wheels and sides.

- 1 foam projection system on vehicles to allow the detergent to act.

- 1 product spraying system for disinfecting and/or decontaminating the interior and exterior of vehicles.

- One or more remote control units, to operate the equipment.

- Side splash protection equipment, with the installation of highly resistant stretched tarpaulins.

- The supply and installation of a modular technical bungalow, when you do not have an existing technical room.

The car wash station is often equipped with a MONTANIER water treatment system in order to reuse the wash water and thus reduce water consumption by more than 80%.

Project information

MONTANIER has developed many specific washing areas for its customers. Communities have been asking MONTANER for years for the design and construction of washing areas for their vehicles.

Based on feedback from MONTANIER for the various community sites, we apply the changes to our new equipment.

The BOM washing tracks and other vehicles are composed of various buried and aerial equipment, in a technical room and on the washing tracks.

A typical washing lane for community vehicles is equipped with:

- 1 high access walkway, allowing the BOM roofs to be washed.

- 1 or 2 automatic reel washing stations, fixed to a pole, allowing ergonomic work at height.

- 1 Low Pressure wash station – High flow (cold water), on the ground with automatic hose reels.

- 1 central gutter with a perpendicular gutter at the end of the track, equipped with a waste collection bin. The weight and handling of these bins are studied to ensure the best ergonomics for the operator.

- 1 EF under-chassis washing station (cold water) with 3 fixed ramps equipped with flat jet nozzles. This system is made up of a horizontal ramp for washing the underframe and 2 vertical ramps for washing the underbody, wheels and sides.

- 1 foam projection system on the vehicles to allow the detergent to act.

- 1 product spray system to disinfect and/or decontaminate the interior and exterior of vehicles.

- 1 or more remote control boxes, to control the equipment.

- Side protection equipment against splashes, with the installation of stretched, very resistant tarpaulins.

- The supply and installation of a modular technical bungalow, when you do not have an existing technical room.

The washing station is often equipped with a MONTANIER water treatment system in order to be able to reuse the washing water and thus reduce water consumption by more than 80%.

+(33) 2 41 67 11 11

+(33) 2 41 67 11 11