Secure washing of the various parts at high pressure.

Handling gloves, protective glass.

- Technical characteristics

| Model | CLM-1150.S (not optional) |

CLM-2150.S (not optional) |

CLM-1150.P (not optional) |

CLM-2150.P (not optional) |

|---|---|---|---|---|

| Energy | 400V+N+E – 5.5kW | 400V+N+E – 5.5kW | 400V+N+E – 5.5kW | 400V+N+E – 5.5kW |

| MAX Flow | 15L/min | 15L/min | 15L/min | 15L/min |

| Pressure | 60 to 150 bar | 60 to 150 bar | 60 to 150 bar | 60 to 150 bar |

| Dim. (L x W x H) |

1200 x 900 x 1850mm | 2000 x 900 x 1850mm | 1200 x 900 x 1850mm | 2000 x 900 x 1850mm |

| MAX GVW weight | 550kg | 850kg | 550kg | 850kg |

| Number used | 1 | 1 | 1 | 1 |

| Hot water | 55°C max | 55°C max | 55°C max | 55°C max |

| Finishing | Standard | Standard | Pharma | Pharma |

| Standard deadlines | 12 weeks | 12 weeks | 12 weeks | 12 weeks |

- Key points

Glove boxes for personal protection (1 or 2 pairs depending on the type of Tetra CLM). Washing using a high pressure lance or rotating nozzles. Piloting by control box and pedal, allowing you to keep your hands free

Washing chamber made of 304L or 316L stainless steel accessible by a glazed safety glass door, and watertight side doors. The bottom of the enclosure has an inclined design to ensure effective gravity flow during washing, The parts to be washed are placed on HDPE gratings for appropriate hygiene,

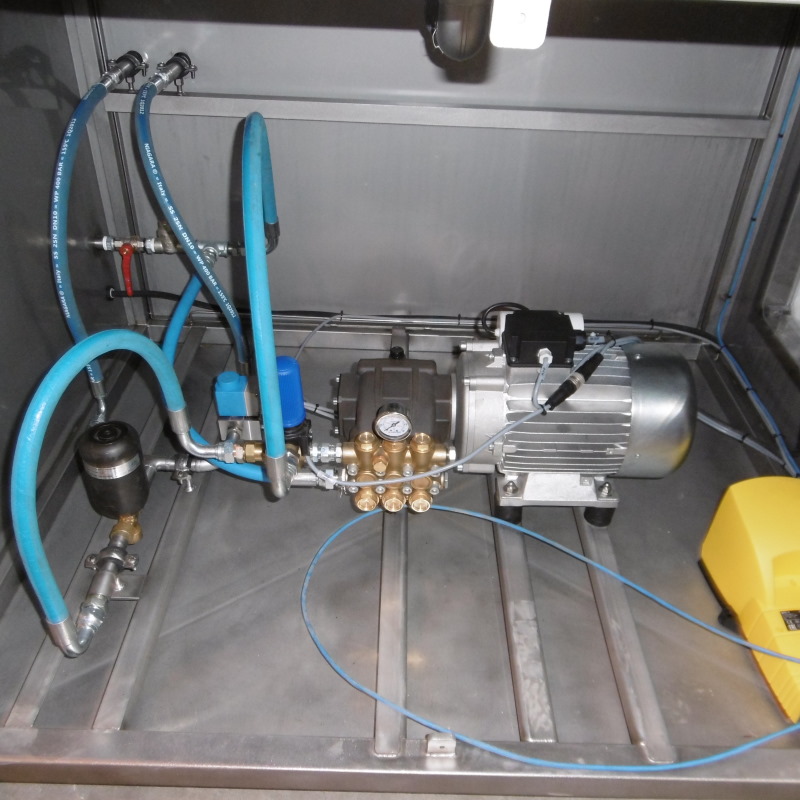

Dedicated technical enclosure accessible by hinged door and removable panels to facilitate maintenance.

Pipes and components in contact with washing water in brass and stainless steel or all stainless steel depending on the finish. The Pharma finish means a 316L stainless steel construction for the enclosure and the pipes. The outer sheets are polished grain 220.

Various possible options: Integrated air extractor, 23L/min pump, injection of detergent/disinfectant product, side openings with access table and flexible entrance and exit curtain.

+(33) 2 41 67 11 11

+(33) 2 41 67 11 11