Our innovations - Transport sector

Since 1976, Montanier teams have been constantly innovating to meet the needs of their customers.

Initially present in the road sector, the company quickly became interested in the urban and road transport sector. It now offers the following innovations:

- Metro washing gantry equipped with a grating-type maintenance platform accessible by a crinoline ladder

- Gantry wash for heavy goods vehicles and buses with stop and go short lane option

- Washing glove for outdoor tank truck

- Technical equipment for interior tank truck washing track

- Underpass washing tunnel for metro with simplified, quick and accessible maintenance

- Washing tunnel on parade for large retro front bus

- Remote maintenance of our washing machines via GSM / 3G / 4G for feedback on a technical malfunction in order to optimize troubleshooting time

- Optimization of city water consumption

- Recycling channels treating 80% of washing water

- High-pressure low-flow chassis wash ramps, mobile or fixed, with automatic start and stop

- Hot and/or cold water high-pressure washing stations on automatic reel or garland rails

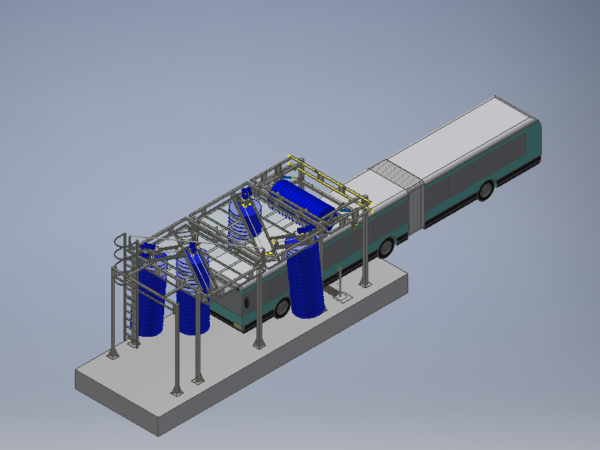

Bus wash tunnel with large rearview mirrors

Montanier has developed a wash tunnel for buses with large rearview mirrors. This innovative tunnel wash system allows for the continuous washing of buses with forward-facing rearview mirrors. To achieve this, the layout of the side brush conveyors and the tunnel structure itself have been redesigned. The goal is to allow buses with large rearview mirrors to be washed continuously while maintaining wash quality and a cycle time of 1 to 1.5 minutes. Furthermore, the wash tunnel incorporates a speed controller to regulate the bus's approach speed. If the approach speed exceeds 5 km/h, the wash tunnel does not activate. Conversely, if the speed is below 5 km/h, the wash tunnel operates to ensure a high-quality wash and prevent damage to the washing machine and the vehicle.

Read More

Drying gantry for telescopic handlers

MONTANIER developed a drying gantry for MANITOU's telescopic handlers prior to paint touch-ups. This equipment complements a wash bay. We use an energy-efficient natural gas boiler to heat the gantry. We installed no fewer than nine drying turbines on the gantry: three on each side with wide nozzles, and three turbines with motorized nozzles at the top. To ensure the vehicle is dried as closely as possible, adapting to the geometry of all machines, two 3D cameras control the three nozzles.

Read More

+(33) 2 41 67 11 11

+(33) 2 41 67 11 11