Info projet

Our R&D team has innovated by developing an in-line tube washing tunnel. In order to be able to switch to hydro paint in its production line, our client, a major player in the manufacture of technical tubes, trusted us to install an in-line washing tunnel, allowing it to achieve the rate with an efficiency of grips paint flawlessly.

Our client’s need was to have continuous washing 24 hours a day – 5 days a week of Ø 7” (177.8 mm) steel tubes for the external degreasing of the tubes before application of hydro paint.

Following the various tests carried out by our company before the project, a washing pressure of 180 Bars was defined, at a temperature of 70°C, with the addition of alkaline detergent (40g/l), with a water flow of 6000 l/h, necessary to supply 1 HP washing ramp with 15 nozzles of 400 l/h each (i.e. 6000 l/h in recycled water).

From these elements, we provided it with a set of equipment ensuring these washing characteristics, with the service of treatment and recycling of the washing water, filtered at 10 µ, free of any oil/grease residue and any smell.

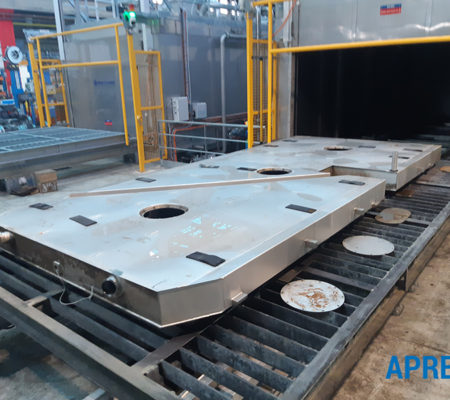

Thanks to the washing tunnel that we have set up, in line, on our client’s production line, added to the high pressure technical unit, the gas boiler, the washing water recycling channel and the blowing system tubes, our customer can now paint their tubes with hydro paint, with perfect manufacturing quality.