Info projet

Our R&D team has developed a train parts washing tunnel for the SNCF.

Our customer had a triple problem for the washing of his parts of different volumes and masses:

- Have a tunnel for efficient washing

- Provide user security for tunnel usage

- Work with the recycling of very dirty water, in order to limit the consumption of water, product and energy

MONTANIER responded to the 3 issues by carrying out the following actions:

- Custom design of washing tunnels based on customer input data and MONTANIER experience for efficient washing

- Adaptation of the best safety measures for operators with the realization of a risk analysis in collaboration with APAVE

- Establishment of a treatment and recycling chain for washing water to save energy and consumption

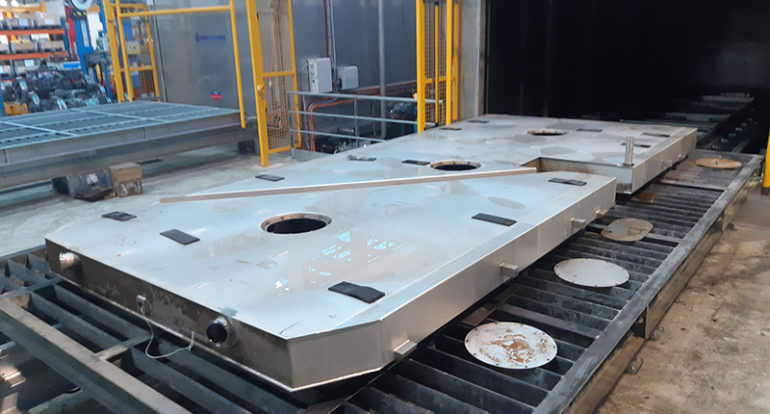

In order to meet the needs of our client, we have created 2 small washing tunnels, with a side-by-side layout, in order to have a sufficient loading / unloading area.

The realization of 2 tunnels offered several technical advantages:

- Installation in the proposed area (20 m x 11.30 m).

- Immediately have the additional surface for loading and unloading the washing trays (50 m² +/-)

- Allow loading / unloading in masked time, during washing

- Ensure the preventive or curative maintenance of a tunnel by continuing the washing on the second tunnel

- Ensure a washing volume higher than the specifications.

- Each of the 2 tunnels washing a surface of Lg 5.20 mx width 3.10 m = 16.12 m² per 3h30 cycle, i.e. 32.24 m² per tunnel, i.e. 64.48 m² for the 2 tunnels per 8h00 shift.</li >

- For reasons of economy, the tunnels benefit from gas heating of the washing water.