Info projet

Our client had to set up cabins allowing him to carry out pressure tests on an explosion-proof electrical box (ADF), in series or in development, allowing him to ensure compliance with the standards in force and standardized test procedures. .

Montanier provided a positive response, and designed a solution allowing INERIS to carry out its tests in accordance with the standard and in a repeatable manner, with:

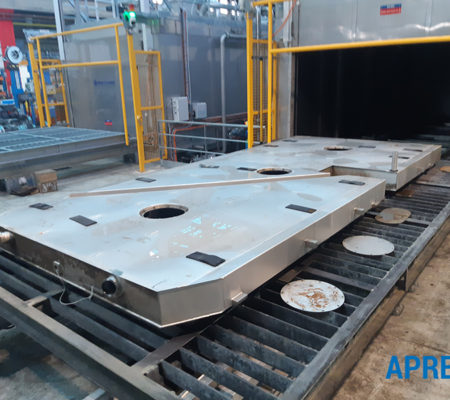

- 1 high and medium pressure technical skid.

- 1 equipped test cabin.

- 1 test management screen with recording.

During this design, Montanier studied the standards in force, and technically transcribed their strict application in the equipment.

Description of the equipment produced:

Installation of a water booster unit with an adjustable pressure of 2 to 60 bars and a water flow of 8 m3/H. max.

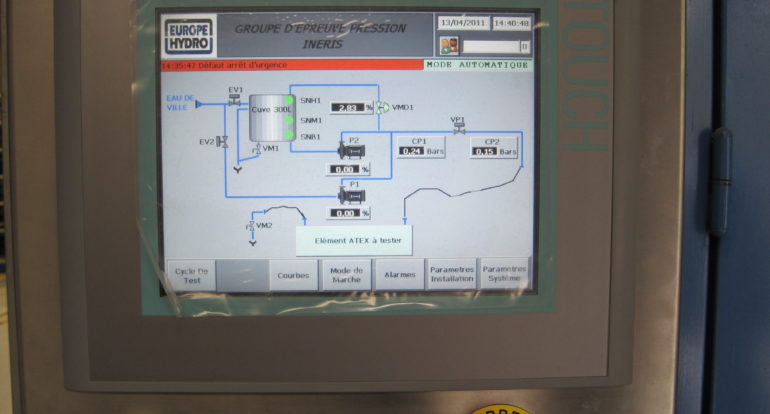

The new HP group allows from a touch screen control box, placed next to the entrance door of the test room, by means of two water suppressor pumps, to carry out the various tests.

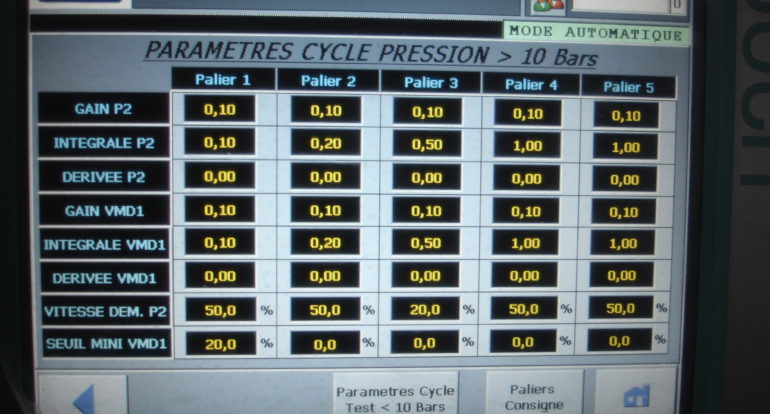

A first centrifugal pump performs tests from 2 to 10 bars at a flow rate of 8m3/H, the second high-pressure pump performs tests from 10 to 60 bars at a maximum flow rate of 8m3/H as well.

Fault information stops the cycle if the pressure is not maintained for the programmed duration.

Mode of operation:

After connecting the equipment to be tested in the test cabin, the operator selects, on the touch screen, the mode of the test:

Pump I – pressure from 2 to 10 bar, or Pump II – pressure from 10 to 60 bar

He can then program the pressure of the test and its duration.

The test cycle proceeds with a slow start slope, followed by holding at the test pressure for the programmed duration, followed by a decompression for its shutdown.

A USB port on the front of the box allows editing of the test parameters: date, time, pressure requested, pressure and duration obtained.

Working principle:

Pressure regulation is ensured by an analog pressure sensor via communication (RS232) with the PLC. The speed of the electric motor of the HP pump is controlled by an electronic frequency variator (0 to 50 Hz).

An electric modulating by-pass valve (4/20 mA) ensures a proportional discharge in the buffer tank, depending on the pressure requested and the leak volumes required for the test.