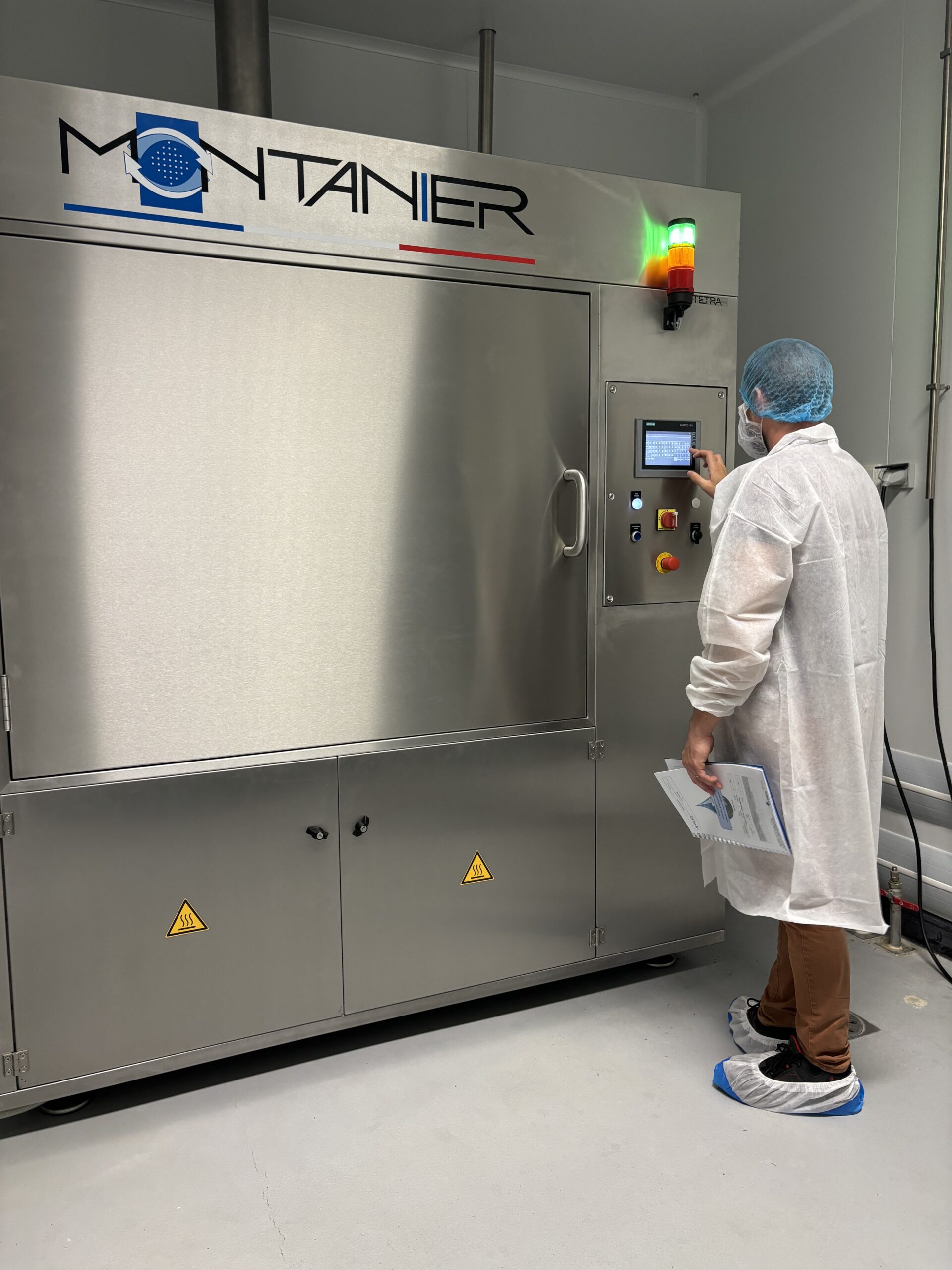

Washing, disinfecting, and drying utensils and equipment: buckets, pots, collars, clamps, seals, drums, etc

A wide range of products catering to manufacturers in the pharmaceutical and cosmetics sectors. For over 50 years, we have supported our clients at every stage of their production to facilitate and optimize their washing processes, while maintaining a high level of quality and technical expertise.

The biggest brands in the pharmaceutical and cosmetics industry trust us.

- Key points

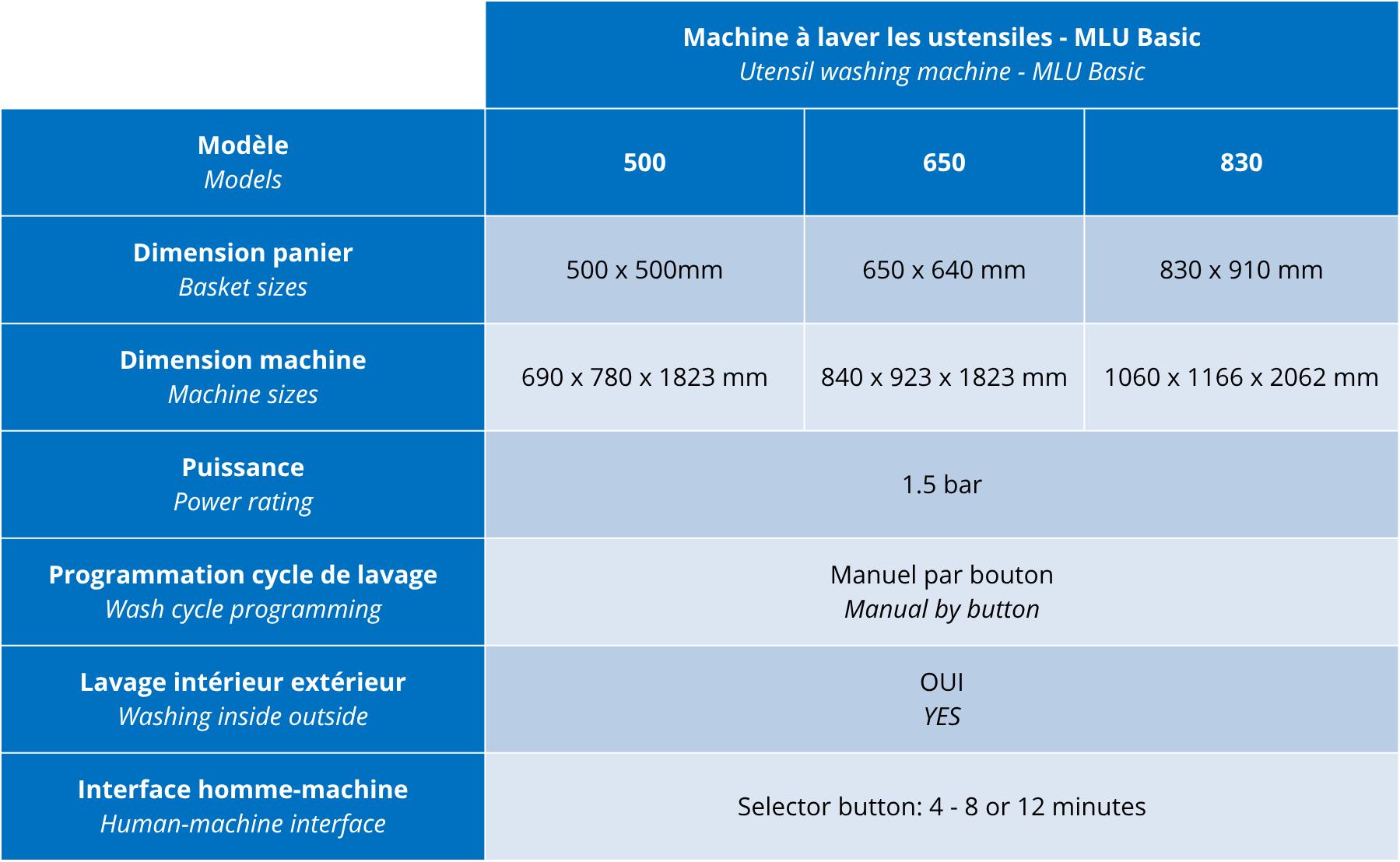

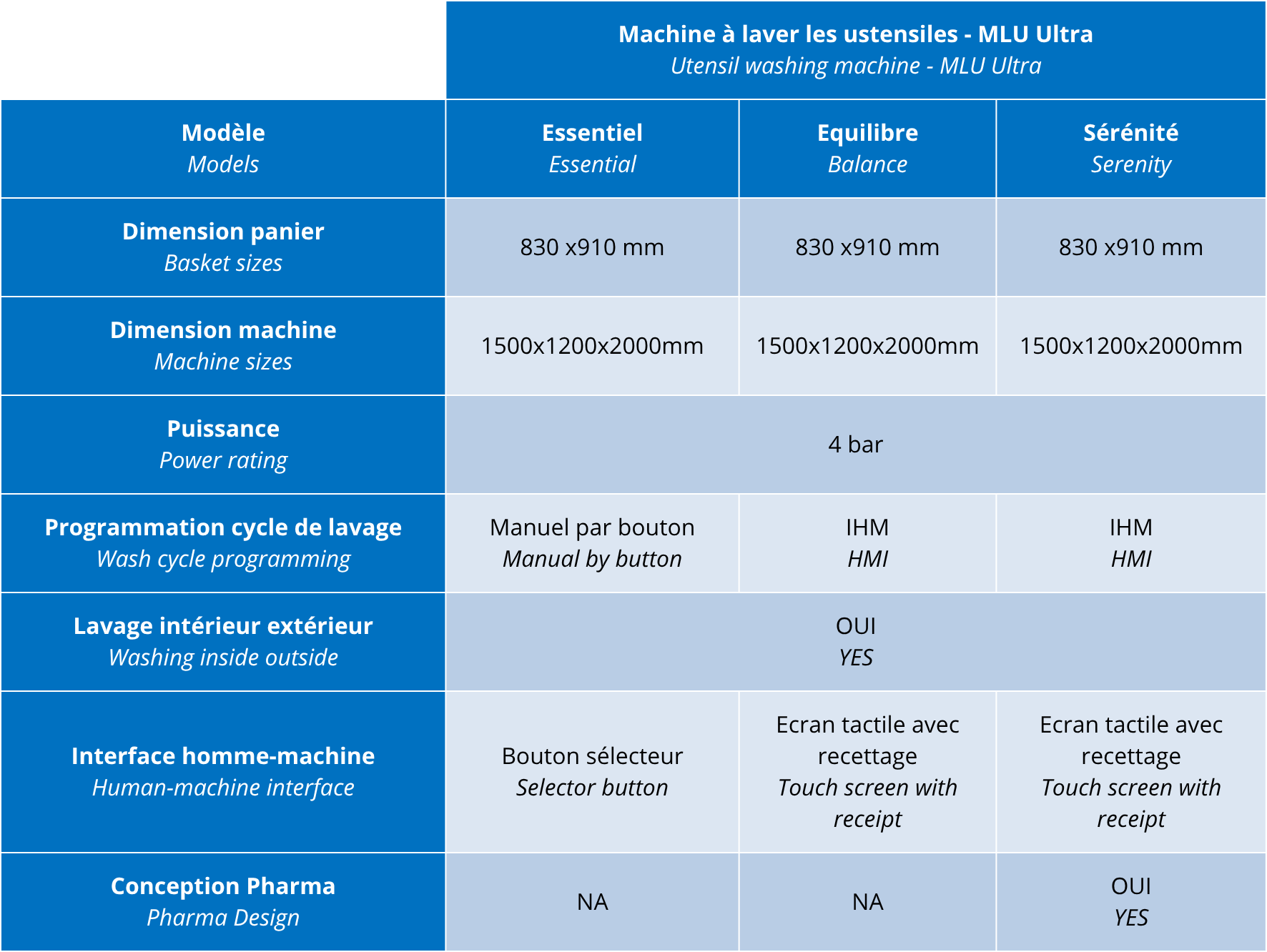

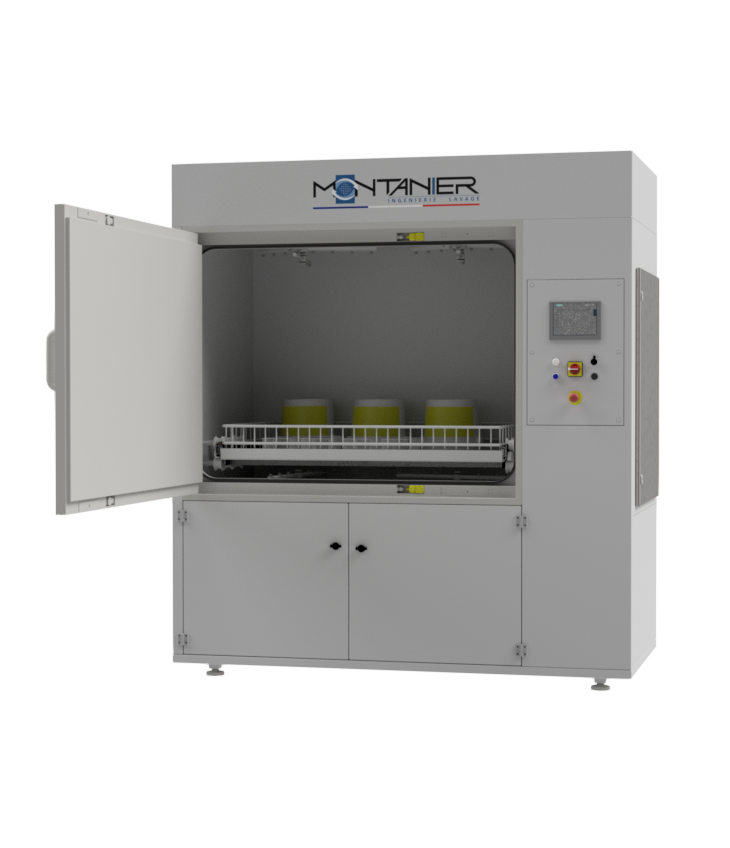

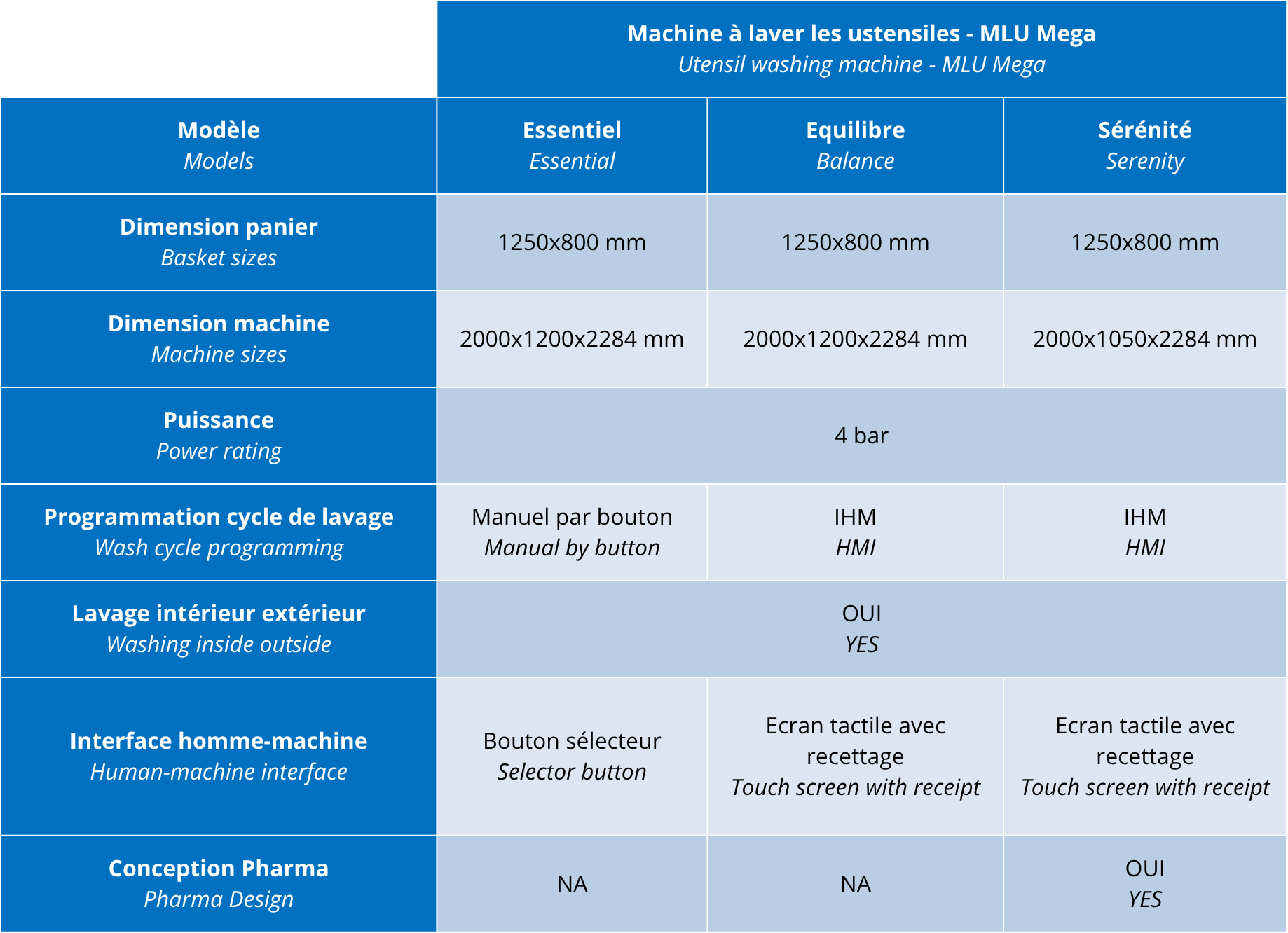

The MLU allows you to wash your various utensils. The MLU is the most efficient on the market. Placed in a basket, the items are washed using rotating arms positioned above and below. Washing is carried out by high-flow, low-pressure circulation.

Washing enclosure made of stainless steel, with different sizes of cabins and baskets.

Dedicated technical enclosure accessible via hinged or pivoting door and removable panels to facilitate maintenance.

Stainless steel piping and enclosure. Slopes respected to guarantee gravity flow.

8 possible options: Drying, additional product injection, custom washing basket, transfer trolley for basket, cycle traceability possible by saving and printing tickets, ball basket, tubular exchanger, swing doors.

+33 2 41 67 11 11

+33 2 41 67 11 11