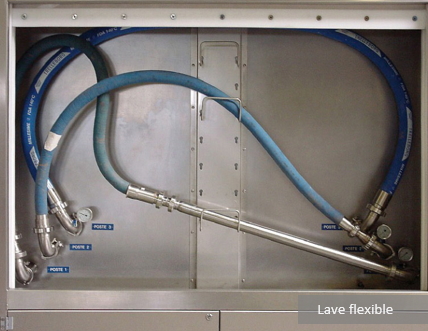

3-station washing by circulating hot water in both directions.

- Technical specifications

| Model | CLF 3x42 | CLF 1x42 |

|---|---|---|

| Energy | 400V+N+T - 30A – 16.5 kW | 400V+N+T - 30A – 16.5 kW |

| MAXIMUM flow rate | 40 m3/h | 40 m3/h |

| Dimensions (L x W x H) |

2350 x 1150 x 2300 mm | 2350 x 1150 x 2300 mm |

| Maximum Gross Vehicle Weight | 1200 kg | 1200 kg |

| Hot water | 55 to 85°C | 55 to 85°C |

| Standard lead times | 24 weeks | 24 weeks |

- Key points

One to three stations allow for the washing of hoses with a diameter of 25 to 60 mm and a length of 1.5 m to 3.5 m. The hoses can be connected end-to-end to increase the washing rate per cycle. Washing is possible in both directions of travel.

316L stainless steel wash recirculation tank with hygienic bottom design to ensure efficient gravity flow during tank draining and rinsing.

The washing chamber is enclosed by a double door or a flexible curtain. A safety sensor prevents the cycle from running when the chamber is open

Piping and components in contact with rinsing water made of 316L stainless steel with respect to slopes to ensure gravity flow.

Human-machine interface managed via touchscreen. Cycle traceability possible through saving and printing tickets.

7 options available: Hose adapters, end-of-cycle drying, process water utility, clean compressed air purge, 1-station drum emptying pump washing, supervision by audit trail and compliance with FDA 21 CFR PART 11, curtain door.

+33 2 41 67 11 11

+33 2 41 67 11 11